Tension spring

Tension spring

- Wire thickness: 0.15mm – 4.00mm

- Wire cross sections: Round,Squre or Oval

- Materials: Carbon steel, Stainless wires, non-ferrous spring wires,special alloys

- Application examples: braking systems, pedals, cup holders, soft close drawer systems, Health Equipments

About Extension Springs

Extension springs resist pulling forces by stretching and returning to their original shape. They feature hooks or loops for attachment and are used in automotive,

industrial, and agricultural applications. Common in garage doors, trampolines, and machinery, they are made from materials like stainless and carbon steel for

durability.

How Extension Springs Work

Extension springs are designed to absorb and store energy as well as create a resistance to a pulling force. The “initial tension” is created during manufacturing

when the wire is rotated backwards during coiling. It is initial tension that determines how tightly together an extension spring is coiled. When you pull the spring

apart, you are undoing the rotation, which develops force or initial tension. Initial tension can be manipulated to achieve the load requirements of your particular

application.

Extension Spring Manufacturing

If you are looking for industry-leading expertise for extension springs, you’ve come to the right place. Our teams are comprised of experienced manufacturing

technicians and engineering experts who are committed to developing the right products to suit your needs. Our experts can produce extension springs of various

thicknesses and lengths to suite your requirements.

Industries

Wire forming is used in markets such as lawn and garden, power equipment, agriculture, industrial, health care, appliances and furniture, farm equipment and

consumer goods.

Material

We also offer a variety of treatment and finishing

options for custom springs made from standard

or specialty materials. Certifications of

conformance for geometric tolerances for stock

springs are available upon request. Material

certifications are available for custom springs.

Wire Sizes & End Types

Our extension springs can be manufactured with

a selection of commonly requested or specialty

finishes.

Wire Types

We produce extension springs from both bar and

wire stock in a variety of thicknesses through both

hot and cold coiling methods. More details are listed

below:

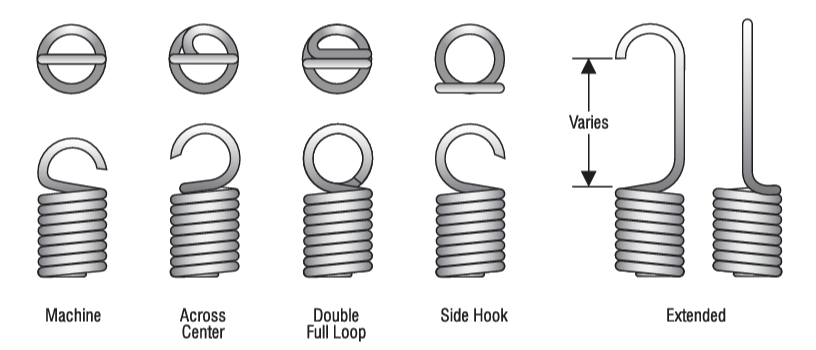

Ends Types

The ends on the extension springs offered in our

stock inventory are the common machine-made

hook and full-loop configurations and include many

varieties of extension springs with hook ends. The

hooks or loops may have an across center transition

of the last coil before forming the hook or loop. The

angle between hook/loop planes (end position) is

random. If you need a specific end

configuration, contact us for design support and

quoting.

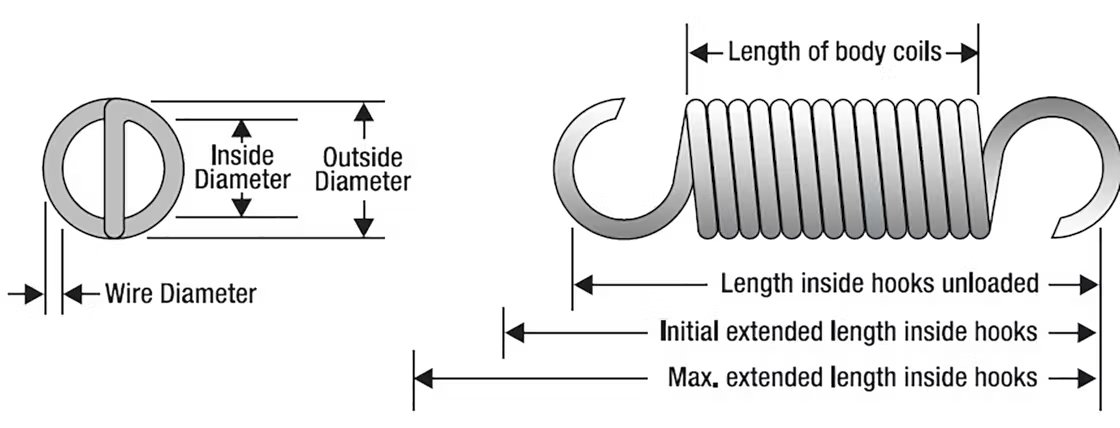

Measurements

To accurately measure an extension spring, follow the steps below.

• Hold the spring in one hand, and the calipers in the other hand.

• Place the calipers across the outside coil, either at the end or the center of the spring. This is called the Outside Diameter (O.D.).

• Place the calipers on the wire at one end of the body coil of the spring. This is called the Wire or Material Size.

• Place the calipers (or tape measure) on the full length of the spring, inside the hooks. This is called the Length (L.I.H.). (see diagram for example)

• Hold the spring in one hand, and the calipers in the other hand.

• Place the calipers across the outside coil, either at the end or the center of the spring. This is called the Outside Diameter (O.D.).

• Place the calipers on the wire at one end of the body coil of the spring. This is called the Wire or Material Size.

• Place the calipers (or tape measure) on the full length of the spring, inside the hooks. This is called the Length (L.I.H.). (see diagram for example)