Torsion

Torsion

- Wire thicknesses: 0.30 mm – 6.00 mm

- Wire cross sections:Round,Rectangular,Sqaure and Ova

- Materials: Carbon steel, Stainless wires, non-ferrous spring wires,special alloys

- Application example: Actuators, Door locking systems, sun protection systems,WM Top Lids

About Torsion Springs

How Torsion Springs Work

Life Expectancy of a Torsion Spring

Types of Torsion Springs: Single vs Double Torsion Springs

Torsion Spring Configurations

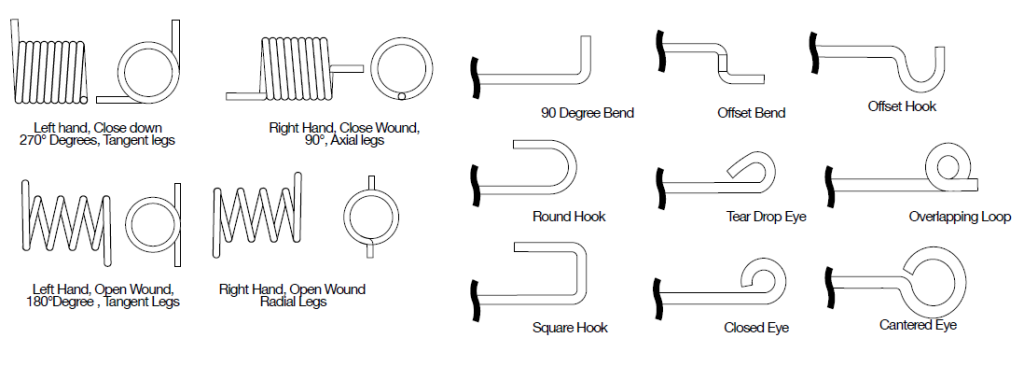

Torsion Spring End Types

Material

Wire Sizes & End Types

Wire Types

Typical Torsion Spring Tolerances

How Are Torsion Springs Designed & Configured?

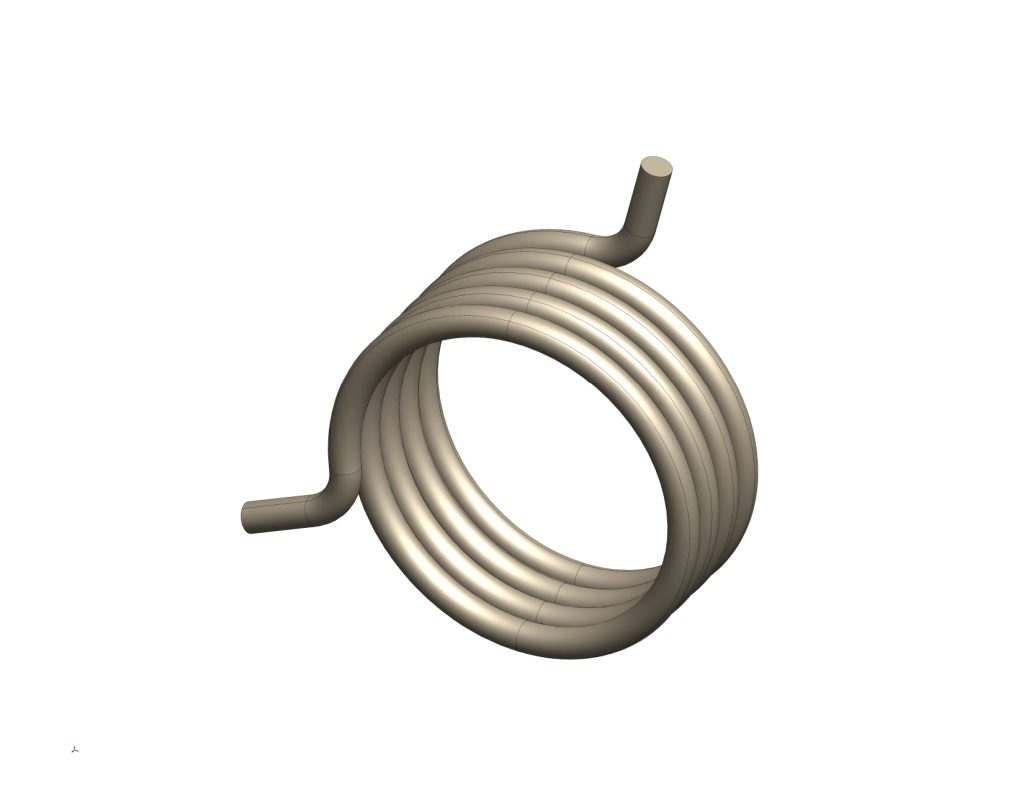

The torsion spring configuration is designed for the purpose of storing and releasing angular energy or for the purpose of statically holding a mechanism in place

by deflecting the legs about the body center line axis. A spring of this type will reduce in body diameter and increase slightly in body length when deflected in the

preferred direction of the fabricated wind.

When designing a torsion spring, it’s important to consider your application and whether you will need round, rectangular, or shaped wire, such as square wire.

The simplest and most common torsion spring designs are single body torsion springs made from rectangular wire with straight ends, although this design format

can be modified with bends and formed shaped.

The direction of the fabricated wind can also be important for torsion spring applications due to the leg bearing/attachment location having to be on the left or right

side upon assembly. A torsion spring is normally supported by a rod (mandrel) that is coincident with the theoretical hingeline of the final product.

Double torsion spring designs are more complex and will need to consider manufacturing method. Double torsion springs are coiled from the center, as opposed

to single torsion springs, which are coiled from the ends. For details on torsion spring design for both single and double body torsion springs, reach out to our

engineering team through our Ask an Expert form.

How to Measure a Torsion Spring

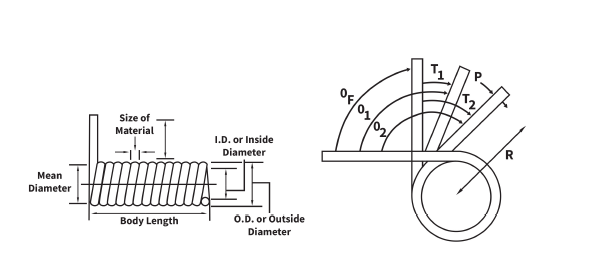

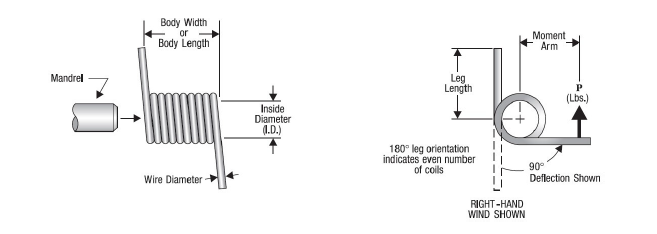

Correct dimensions are crucial in identifying the right spring for your application. Use the steps and diagram below to measure accurately measure your

torsion springs.

- Hold the spring in one hand, and the calipers in the other hand.

- Place the calliper “teeth” on the inside diameter. This is called the Inside Diameter (I.D.).

- Place the calipers on the “leg” to measure the wire. This is called Material Size (or Wire Diameter).

- Place the calipers on the working coils of the spring. This is called the Body Length. Place the calipers on the working coils of the spring. This is called

the Body Length. - Count the total coils, beginning at one end, just under where the leg leaves the body. Count to the other end, all full coils, and any fraction thereof.

This is called the Number of Coils and determines leg position. i.e. 90°, 180°, etc. - Determine the direction of the coil (Wind Direction). See diagram for hand/finger illustration. Right Hand Wind or Left Hand Wind.