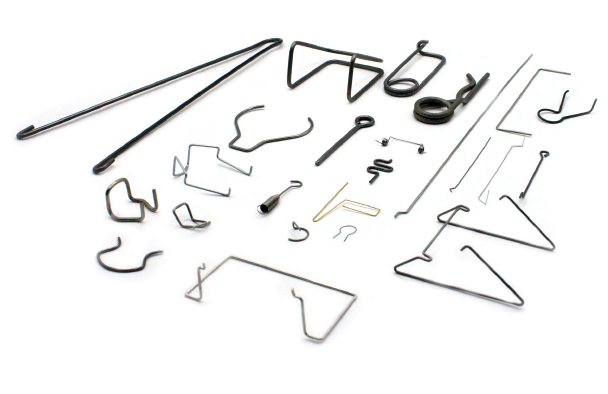

Wire form

Wire form

- Wire thicknesses: 0.50mm – 6.00 mm+

- Wire cross sections: round, square

- Materials:Carbon steel, Stainless wires, non-ferrous spring wires,special alloys

- Application example: tank systems, seat structure, door systems

About Wire Forms

Wire forms are have endless configuration options, making them frequent components used in both industrial and general use consumer products. They are

made from shaped wire and can include parts used in lightbulb filaments, musical instruments, clocks, medical trays, pins, pegs, and rivets

Wire Form Manufacturing Capabilities

Wire forms have the unique ability to join complex products with tough design constraints. Ranoson Springs Pvt Ltd offers a variety of wire forms to suit your needs,

including formed and stamped wire forms, multiple-bend forms, headed forms, and linkage arms.

We have the equipment and capabilities to produce the wire forms you’re looking for, in the sizes, configurations and materials you need. With complete control of production, we’re a wire forming manufacturer that ensures both a high-quality product and fast turnaround.

We have the equipment and capabilities to produce the wire forms you’re looking for, in the sizes, configurations and materials you need. With complete control of production, we’re a wire forming manufacturer that ensures both a high-quality product and fast turnaround.

Wire Form Manufacturing

Wire forms are created by forming and pressing wire into specific desired configurations in order to complete a job or perform a function. As complex design

experts, Ranoson has the capability to produce wire forms with our advanced machinery, allowing for custom wire form production at ultra-high speeds.

• Multi-axis CNC machining and CNC wire bending services

• Automated and manual wire bending

• Fast turnaround times

• Lengths from 25MM to 300MM and diameters ranging from 0.50mm to 6.00MM.

• In-house secondary services including threading, chamfering, welding, and more

• Variety of material grades

• High quality products ensured with a robust QA process and quality assurance systems .

• Multi-axis CNC machining and CNC wire bending services

• Automated and manual wire bending

• Fast turnaround times

• Lengths from 25MM to 300MM and diameters ranging from 0.50mm to 6.00MM.

• In-house secondary services including threading, chamfering, welding, and more

• Variety of material grades

• High quality products ensured with a robust QA process and quality assurance systems .

Material

We use the highest grades of spring wire in our

custom products. Carbon steels include material

types such as music wire, basic, hard drawn and

oil-tempered chrome silicon & vanadium. We work

in a variety of stainless materials from 302 Stainless

to 316 SS, 17-7 PH and even more exotics. Material

certifications available on request.

Secondary Services

Ranoson Springs offers several secondary

services in-house to produce a wide range of

products at competitive prices and lead times.

Finishes

We perform several finishing and coating

processes as needed for your application. Some

finishes we offer are listed below. If you require a

finish not listed here, contact us for a custom quote

and we will work with you to get the performance

properties you require.

Wire Types

We produce Wire forms from both

Square, Rectangle and Round wire in a

variety of thicknesses through both CNC

Forming and Manual methods. More

details are listed below:

- Maximum Wire Dia – 7.00MM

- Minimum Wire Dia – 0.40MM

- Width – 6.00~1.50MM

- Thickness – 6.00~1.50MM